Southern Taiwan University of Science and Technology Presents Industry–Academia R&D Achievements in Exosome Technology; Techniques Transferred to Japanese Team for Experimental Validation

Southern Taiwan University of Science and Technology collaborated with Taiwan Exosome Co. on industry–academia–research initiatives. After completing pharmacological and animal studies at Chiayi Chang Gung Memorial Hospital and Chia Nan University of Pharmacy and Science, the partners held a “Results Handover Presentation” today, announcing the successful breakthrough of high-purity manufacturing processes for six types of plant-derived exosomes and key NK exosome technologies for kidney repair. These achievements demonstrated positive effects on corneal wound healing, antibacterial activity, and arthritis inhibition.

With the rapid rise of exosome applications, many companies in Taiwan have invested in research and development. However, there is a widespread misconception that stem cell–derived exosomes are merely aesthetic or wellness products. Southern Taiwan University of Science and Technology emphasized that the core manufacturing processes and research data from this collaboration will first be applied in human trials by a Japanese team in cooperation with Kumamoto University Hospital, followed by mass production planning, with Taiwan positioned as a key market.

The university stated that the laboratory team led by Distinguished Professor Chu Chun-Chieh of the Institute of Biotechnology collaborated closely with industry partners in key areas such as fermentation engineering, separation and purification, and process scale-up, gradually establishing standardized, reproducible, and scalable manufacturing processes. In particular, plant-derived exosome technologies face industry bottlenecks such as difficulty in maintaining bioactivity and challenges in large-scale production. The team successfully built a stable and production-feasible process platform, completing standardized process parameters and quality control systems for six species, including Chlorella, Platymonas subcordiformis, Ulva, plant-derived lactic acid bacteria, Ganoderma lucidum, and Cymbidium orchids.

Relevant data showed that the process performed well in maintaining key physiological activities of exosomes, achieving tangible results in antioxidant capacity, tissue repair, and physiological function regulation. These outcomes have become an important technological foundation for the company’s subsequent product development and applications.

The university noted that these achievements stemmed from long-term, stable collaboration between academia and industry. From the early stages of research, industry partners proposed practical process and product requirements, while the university research team designed and validated technologies according to industrial standards. Graduate students and advanced technical professionals were simultaneously involved in the R&D process, forming a “demand-driven R&D × talent co-development” collaboration framework that effectively shortened the translation timeline from laboratory research to production lines.

In addition to industrial applications of plant-derived exosomes, the university also collaborated with industry partners on research targeting chronic kidney disease. Animal experiments revealed that NK exosomes possess immunomodulatory and anti-inflammatory potential, effectively reducing renal inflammation and mitigating damage to glomerular and tubular structures. These findings demonstrate promising translational potential in kidney repair and precision medicine, laying a foundation for subsequent preclinical studies.

The university indicated that after key technologies were validated, the university and industry partners jointly established R&D data and process models. These have already been adopted as critical references for the construction of automated mass production lines at the KAiTA Artificial Intelligence Technology Park in Kumamoto, Japan. This achievement symbolizes the maturity of the collaborative R&D partnership and represents a concrete step toward integration into international industrial and regulatory systems.

Vice President for Academic Affairs Wang Chen-Chien stated that the deep collaboration between Southern Taiwan University of Science and Technology and industry partners fully demonstrates the critical value of the technical and vocational education system in forward-looking biomedical R&D and high-level talent cultivation. Both parties will continue to focus on industry needs, deepen research in regenerative medicine, biomedical manufacturing, and precision medicine, and cultivate R&D talent with international perspectives and practical capabilities through industry–academia co-training and cross-border collaboration mechanisms, further strengthening Taiwan’s global competitiveness in the biotechnology industry.

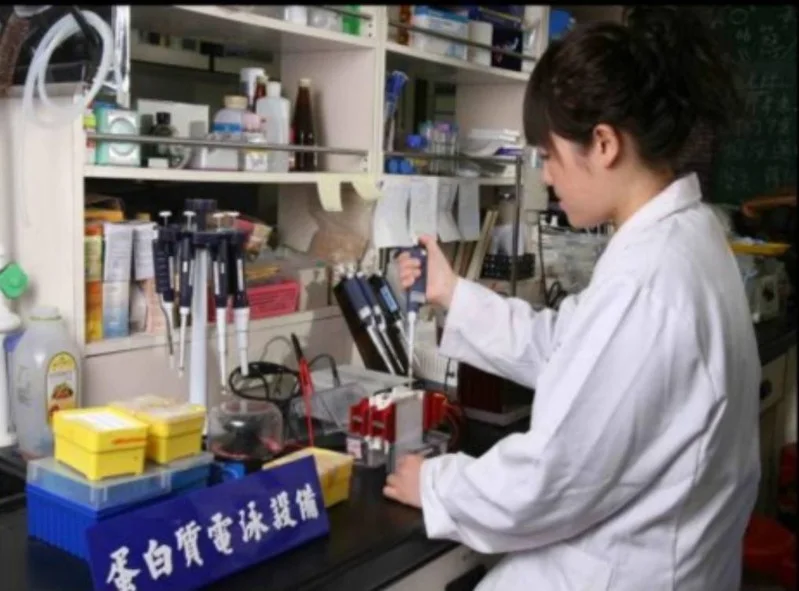

The laboratory team led by Distinguished Professor Chu Chun-Chieh at the Institute of Biotechnology collaborated closely with industry partners in key areas such as fermentation engineering, separation and purification, and process scale-up, gradually establishing standardized, reproducible, and scalable manufacturing processes. Photo provided by the Institute of Biotechnology.

The laboratory team led by Distinguished Professor Chu Chun-Chieh at the Institute of Biotechnology collaborated closely with industry partners in key areas such as fermentation engineering, separation and purification, and process scale-up, gradually establishing standardized, reproducible, and scalable manufacturing processes. Photo provided by the Institute of Biotechnology.

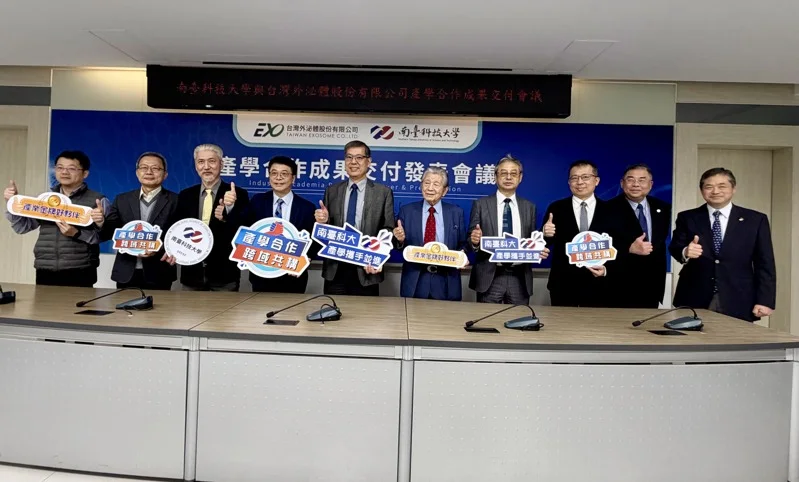

Southern Taiwan University of Science and Technology and Taiwan Exosome Co. jointly conducted industry–academia–research collaboration. Pharmacological and animal studies were completed at Chiayi Chang Gung Memorial Hospital and Chia Nan University of Pharmacy and Science. The “Results Handover Presentation” was held today. Photo by reporter Chou Tsung-chen.

Southern Taiwan University of Science and Technology and Taiwan Exosome Co. jointly conducted industry–academia–research collaboration. Pharmacological and animal studies were completed at Chiayi Chang Gung Memorial Hospital and Chia Nan University of Pharmacy and Science. The “Results Handover Presentation” was held today. Photo by reporter Chou Tsung-chen.